1. Core Characteristics of Diamond Tools

Diamond tools are a type of tool made by utilizing the ultra-high hardness and wear resistance of diamond (natural or synthetic). They are widely used in cutting, grinding, and polishing hard and brittle materials such as stone, glass, ceramics, metals, and semiconductors. Their core characteristics include:

Ultra-high hardness and wear resistance: Diamond is much harder than most other materials (such as stone, glass, and cemented carbide), making the tool edge/abrasive grains less susceptible to wear.

Excellent machining efficiency: Due to its high hardness, diamond tools can quickly “cut” or “grind” hard and brittle materials, significantly improving machining efficiency.

Excellent thermal conductivity and heat dissipation: Diamond’s thermal conductivity is over five times that of copper. Heat generated during machining is quickly transferred to the tool base or cooling medium, preventing deformation and cracking of the workpiece due to localized high temperatures. Strong Chemical Stability: Diamond does not react with chemicals such as acids and alkalis at room temperature, but only reacts with oxygen and other substances at high temperatures (>800°C). Therefore, machining precision is more stable.

2. Core Advantages of Vacuum Brazing Furnaces in Diamond Tool Brazing

Reduces Oxidation and Increases Tool Life: The high-temperature vacuum environment effectively removes most reactive gases such as oxygen and nitrogen, significantly reducing oxidation reactions during the brazing process.

Improves Braze Bond Strength and Avoids the Risk of “Grit” (Small Grain Drops): In a vacuum environment, there is no oxide scale to hinder the brazing process, allowing the brazing material to more evenly wet the diamond and substrate surfaces. Furthermore, the high temperature promotes elemental diffusion between the brazing material and the substrate, and between the brazing material and the diamond, thereby improving bond strength. The vacuum environment also removes volatiles generated during the brazing process, resulting in a dense, defect-free brazing joint and further enhancing joint reliability. 3. High temperature uniformity ensures tool dimensional accuracy and consistency.

Multi-zone heating within the furnace ensures excellent temperature uniformity, preventing substrate deformation or localized damage to the diamond due to local overheating, ensuring the dimensional accuracy of the finished tool and making it suitable for large-scale production.

Reduced reliance on flux, simplified post-processing, and reduced contamination.

Compatible with complex tool structures and expanding application scenarios. The vacuum furnace heats through thermal radiation, evenly transferring heat to the intricate structure of the tool, ensuring sufficient melting and wetting of the brazing filler metal in these areas, achieving reliable bonding across the entire area. Compatible with a variety of substrates and brazing fillers: Whether it’s carbon steel, stainless steel, or cemented carbide substrates, or copper-, silver-, or nickel-based brazing fillers, the high-temperature vacuum brazing furnace can be adapted by adjusting the vacuum level and temperature profile (heating rate and holding time), expanding the tool’s application areas (such as high-precision machining applications in aerospace, electronics, and information technology).

3. Key Parameters and Configuration Selection for a Vacuum Furnace Dedicated for Diamond Tool Brazing

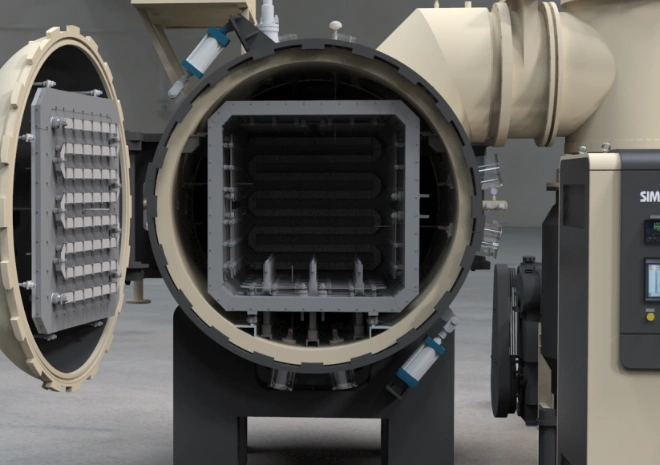

Due to the unique process requirements of diamond tool brazing, a dedicated vacuum sintering furnace must meet stringent requirements in terms of temperature, vacuum level, structural design, and control system. The specific key configurations and parameters are as follows:

● Core Performance Parameters

Maximum Brazing Temperature: 1300°C, meeting the high-temperature conditions required for diamond tool brazing and ensuring full wetting of the brazing material and complete densification between the substrate and the brazing material;

Furnace Temperature Uniformity: Control accuracy of ±5°C ensures uniform heating of blanks within a batch, preventing temperature deviations from affecting product quality;

Vacuum Level: The ultimate vacuum level can reach 6.7×10⁻³Pa, providing a reliable vacuum environment for impurity removal and oxidation prevention, meeting the requirements for sintering high-purity silicon carbide.

● Key Structural Design

Heating Chamber Design: A circular heating chamber with multiple independent heating zones utilizes the symmetry of the circular space to achieve uniform heat distribution, further improving furnace temperature uniformity.

Heating Elements: Heating elements are available in graphite or molybdenum, offering a variety of heating element materials suitable for different substrate characteristics, improving product quality and the applicability of the vacuum furnace.

Furnace Shell Structure: A double-layer water-cooling jacket efficiently removes excess heat generated during operation, maintaining a stable furnace temperature and preventing damage to the equipment due to localized overheating. The furnace shell is also equipped with a dedicated drain device to regularly remove impurities from the cooling water, ensuring long-term stable operation of the cooling water system and reducing the risk of equipment failure.

● High-Precision Control System

Temperature Control Core: Utilizing the Continental 2604 temperature controller, with a control accuracy of up to ±0.1% F.S. (full scale), this controller precisely matches the complex temperature profiles required for silicon carbide sintering, facilitating process optimization and upgrades. This controller boasts powerful communication and expansion capabilities, supporting no fewer than 888 temperature/time program settings. It implements intelligent PID control and automatic switching of heating control channels, meeting diverse sintering process requirements. Built-in thermocouple burnout redundancy ensures rapid fault location, simplifies troubleshooting, and significantly improves equipment reliability during production.

Low-Voltage Component Configuration: All low-voltage components are sourced from internationally renowned brands such as Siemens, Schneider, and Phoenix Contact. These components offer significant advantages in quality, performance stability, and workmanship, significantly reducing the control system’s failure rate. Furthermore, the high degree of standardization of components from renowned brands allows users to quickly select and replace components should a malfunction occur, minimizing production losses caused by equipment failure.