1. Introduction

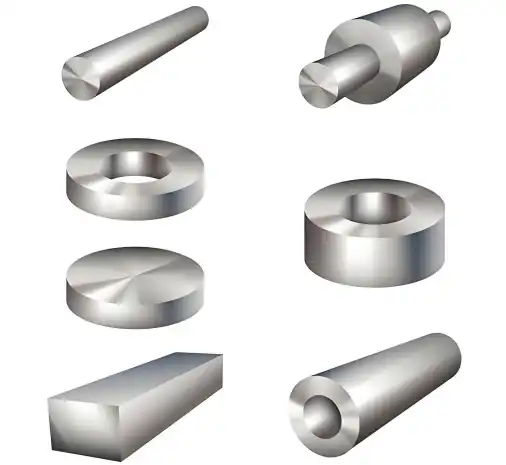

AISI 430 is a ferritic stainless steel with a chromium content between 16% and 18%.Its notable characteristics include strong magnetism and the absence of expensive nickel, thus offering a significant cost advantage while maintaining good corrosion and oxidation resistance. In industrial applications, its excellent thermal conductivity and low thermal expansion coefficient make it widely used in appliance panels, automotive trim, and magnetic induction components in MIM (Metal Injection Molding) processes. It is an ideal material choice that balances aesthetics, magnetic functionality, and cost-effectiveness.

2. Parameters

Vacuum annealing is crucial for AISI 430 stainless steel, as it effectively eliminates processing stress and restores material toughness.While maintaining a bright, non-oxidized surface, it significantly improves corrosion resistance and magnetic permeability.

The main steps for vacuum annealing of AISI 430 stainless steel are as follows:

- 1. Preheating: 500-600℃, holding for 30-60 minutes.

- 2. Heating: Raise the temperature to 780-850℃ at a rate of 10℃/minute.

- 3. Holding: 815-845℃, holding for 1-4 hours.

- 4. Cooling: Slow cooling from 845℃ to 500℃.

Rapid cooling: From 500℃ to room temperature, using nitrogen/argon gas for rapid cooling

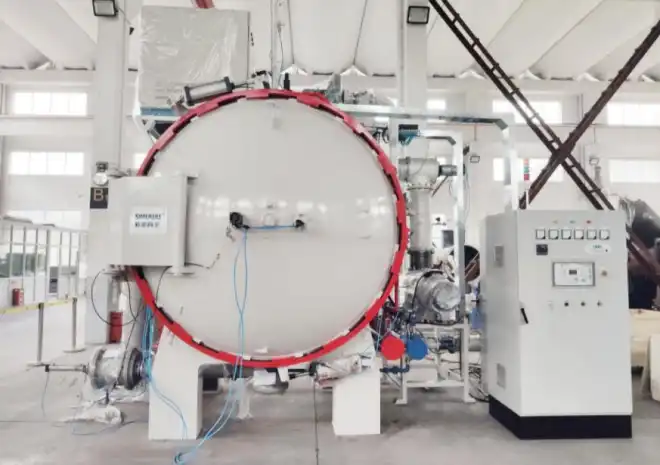

3. SIMUWU Vacuum Annealing Furnace Configuration

SIMUWU RVA-8812 vacuum annealing furnace is equipped with a Siemens S7-1200 PLC, and combined with its extensive process library and robust furnace structure, it can perform this process fully automatically and flawlessly. The specific parameters are as follows:

| Furnace type | Horizontal , single room, internal circulation |

| Loading method | Front loading |

| Max. loading weight | 1000kg (Including jig) |

| Ultimate vacuum (cold furnace, after drying and degassing) | Better than 6*10-³ pa |

| Working vacuum | 6×10-²pa |

| Power supply | 3 Phase 380V (±5% );50Hz |

| Pressure rise rate (cold and empty furnace) | ≤ 0.5 Pa/h |

| Effective working zone ( WxHxL ) | 800×800×1200mm |

| Max.design temperature | 900℃ |

| Working temperature | 850 ℃ |

| Temperature uniformity | 9 points temp testing (±5℃) (standard AMS 2750F) |

| Temperature control accuracy (℃) | S type thermocouple ≤ ±1 ℃ |

| Temperature control instrument accuracy (℃) | ≤ 0.1 ℃ |

| Heating zone | 3 Zones separate temperature control |

| Empty furnace heating rate | 0~25℃ /min (adjustable and controllable rate) |

| Time to heat the workpiece to the required temperature | ≤ 60 min |

| Temperature uniformity (vacuum, empty furnace, 500-1250℃) | ± 5 ℃ |

| Cooling motor power | 18.5 KW |

| Temperature control method | Intelligent programmable temperature controller for automatic temperature control |

| Control method | PLC automatic/manual interlock protection control |

| Max. inflation pressure | <2 bar(absolute pressure) |

| Cooling method | Air cooling/natural cooling |

| Cooling gas | Nitrogen or argon (purity: 99.99% or 99.999%) |

| Cooling rate (empty furnace 1200℃~150℃) | ≤ 30 min |

| Partial pressure pressure | 50-2000Pa manual and automatic control |

| Operation model | Manual/Automatic control |

| Equipment color | Customized |

If you would like to learn more or have any questions, please feel free to contact kevin.liu@vacfurnace.com. SIMUWU will be happy to assist you.