What is a Retarder Cooler?

A retarder cooler, typically referring to a hydraulic retarder cooler, is a heat exchange device installed on heavy trucks, buses, or construction machinery. Its primary function is to transfer the immense heat generated by the hydraulic retarder during braking to the vehicle’s engine cooling system (water circuit), thereby preventing the retarder from overheating and failing.

It is usually made of aluminum alloy (such as AL3003) or stainless steel, as these materials have good thermal conductivity and corrosion resistance.

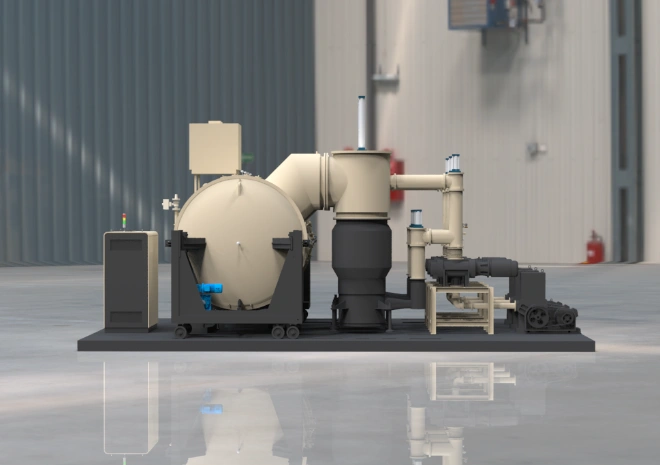

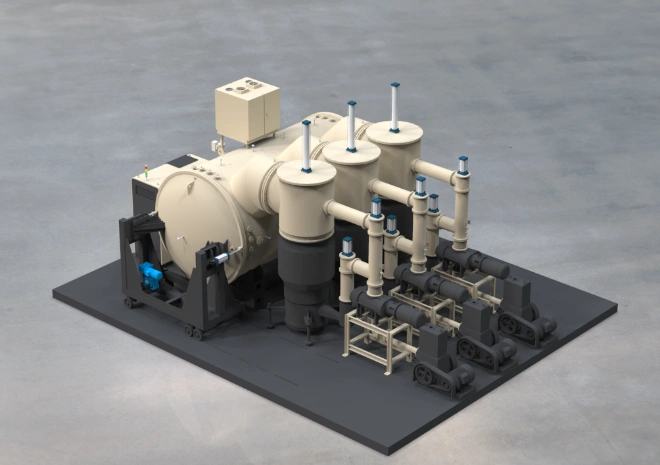

Manufacturing Process: Vacuum Brazing

The following is the specific process for manufacturing a retarder cooler in a SIMUWU vacuum brazing furnace, using AL3003 as the base material and AL4104 as the brazing filler metal:

1. Initial Heating and Degassing:

The temperature is raised from room temperature to 350-400℃, with a heating time of approximately 20-40 minutes, to remove residual gases in the furnace and adsorbed moisture from the workpiece surface.

2. Preheating:

The temperature is maintained at 400℃ for approximately 40-60 minutes to relieve thermal stress and ensure uniform temperature throughout the workpiece, preventing deformation.

3. Heating:

The temperature is raised from 400℃ to 500-560℃, with a heating time of approximately 30-50 minutes. The key point of this step is that the magnesium in AL4104 begins to evaporate significantly at this stage, damaging the oxide film.

4. Brazing and Holding:

The temperature is held at approximately 600℃ for about 8 minutes. The solder melts to form a weld seam. The holding time should not be too long, otherwise erosion will occur.

5. Cooling:

The temperature is lowered from the highest temperature to below 500℃ to rapidly solidify the weld seam and reduce grain boundary embrittlement.

The following are the specific technical parameters of the vacuum brazing furnace required for vacuum brazing of AL3003:

SIMUWU Vacuum Brazing Furnace Specifications

| Furnace design | Horizontal type,front and rear door opening |

|---|---|

| Working zone size | 700(W) x 700(H) x 1000(L)mm |

| Loading capacity | 800kg (with fixture and jigs) |

| Power supply | 380V (3 phase)/50HZ |

| Heating power | 100 KW |

| Installed power | 150 KW |

| Max.design temperature | 750℃ |

| Working temperature | RT(Room Temperature)-700℃ |

| Temperature control accuracy | ±1℃(Vacuum,Empty, 600℃)±1℃ |

| Temperature uniformity | ±5℃, 9 points temp testing±5℃ |

| Temperature control components | PLC |

| Thermal couple | “K” Type |

| Heating rate | 0-20℃/ min |

| Ultimate vacuum degree (drying°assing ) | 6.7×10-4Pa |

| Working vacuum degree | 6.7×10-3Pa |

| Pressure rising rate | ≤0.5Pa/h |

| Temperature control | PLC |

| Control mode | PLC Automatic/manual interlock protectionPLC |

| Equipment color | Customized (user provide RAL color number) |

Contact Us for Professional Solutions

If you have any needs, please feel free to contact us at kevin.liu@vacfurnace.com. I will be happy to assist you.