This article outlines the principles, key parameters, process types, applications, and practical outcomes of vacuum heat treatment across modern industries.

Table of Contents

1. Introduction

Vacuum heat treatment is a modern and advanced thermal process carried out in a vacuum heat treatment furnace.Unlike conventional furnaces, industrial vacuum furnaces operate in a controlled low-pressure environment. This prevents oxidation, decarburization, and surface contamination of metals, resulting in bright, clean parts. With advanced technology from SIMUWU Vacuum Furnace, manufacturers achieve superior consistency and high-quality results.

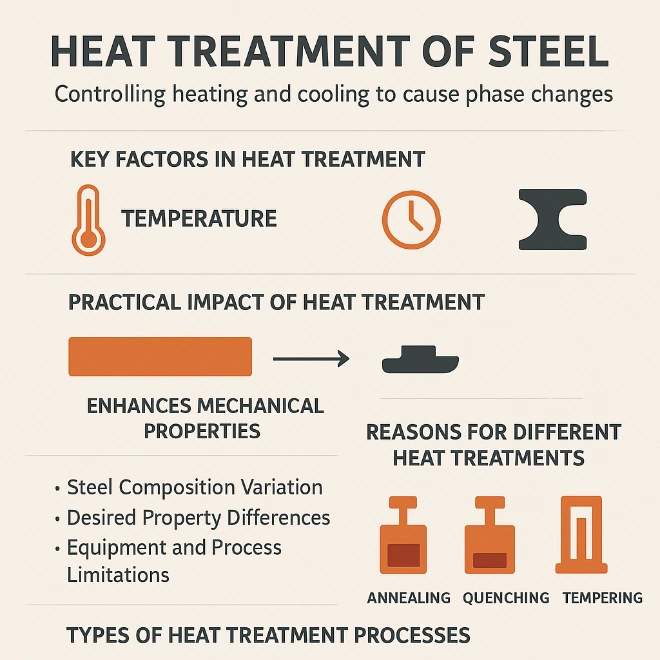

2. Key Factors: Pressure, Temperature, and Time

Vacuum Pressure: The vacuum environment protects the surface and ensures oxide-free metal components.

Temperature: Precise control at austenitizing or tempering levels provides reliable phase transformations.

Time: Correct holding time ensures uniform microstructure and repeatable quality in every batch.

3. Practical Impact

Using a vacuum heat treatment furnace provides:

High hardness and wear resistance after vacuum quenching.

Excellent toughness and reduced brittleness after vacuum tempering.

Bright, oxide-free surfaces that eliminate post-treatment cleaning.

These advantages make vacuum furnaces essential for aerospace, automotive, medical, and tooling applications.

4. Reasons for Choosing Vacuum Heat Treatment

Surface Quality: Demanding industries need oxide-free surfaces.

Complex Alloys: Stainless steels, tool steels, and superalloys respond better in vacuum.

Dimensional Accuracy: Vacuum quenching furnaces minimize distortion compared to traditional methods.

Technology Leadership: As a leading vacuum furnace manufacturer in China, SIMUWU provides advanced solutions for global industries.

5. Types of Processes

Vacuum Annealing Furnace: Softens steel, relieves stress, and ensures bright surfaces.

Vacuum Quenching Furnace: Provides high hardness with controlled distortion.

Vacuum Tempering Furnace: Balances hardness and toughness for quenched parts.

Vacuum Carburizing Furnace (LPC): Produces uniform case hardening for gears and automotive parts.

Vacuum Nitriding Furnace: Enhances fatigue strength and surface hardness.

Vacuum Brazing Furnace: Creates clean, strong joints for aerospace and medical components.

6. Comparison of Outcomes

Surface Quality: Bright and clean, unlike traditional furnaces.

Dimensional Accuracy: Better stability, less deformation.

Mechanical Properties: High hardness, strength, and fatigue resistance.

Consistency: Every cycle in SIMUWU vacuum furnaces ensures reliable results.

7. Applications

Aerospace: Turbine blades, landing gear, precision components.

Automotive: Gears, shafts, bearings, and structural parts.

Medical Devices: Surgical tools, implants, and precision instruments.

Tooling Industry: Cutting tools, molds, dies, and wear-resistant parts.

8. Advantages and Disadvantages

Advantages:

Oxidation-free, bright surface quality.

Precise process control with industrial vacuum furnaces.

Reduced distortion, better dimensional stability.

Compatible with advanced alloys.

Disadvantages:

Higher investment in vacuum heat treatment furnaces.

Longer cycle time for some processes.

9. Conclusion

Vacuum heat treatment is essential for high-performance components in modern industries. With SIMUWU vacuum furnaces, manufacturers gain stable, repeatable, and high-quality results. As a trusted vacuum furnace manufacturer in China, SIMUWU offers advanced vacuum quenching furnaces, vacuum brazing furnaces, and vacuum carburizing furnaces, meeting the toughest global standards.

10. Frequently Asked Questions (FAQ)

Q: What is the advantage of using a vacuum heat treatment furnace?

A: It provides oxidation-free surfaces, precise control, and improved part quality.

Q: Which industries use vacuum heat treatment the most?

A: Aerospace, automotive, medical, and tooling industries.

Q: What types of processes can SIMUWU vacuum furnaces perform?

A: Vacuum annealing, vacuum quenching, vacuum tempering, vacuum carburizing, vacuum nitriding, and vacuum brazing.

Q: How does a vacuum quenching furnace reduce distortion?

A: Uniform gas or oil cooling in a vacuum minimizes stress and deformation.

Q: Is vacuum carburizing better than traditional carburizing?

A: Yes, vacuum carburizing furnaces provide uniform case depth and cleaner surfaces.

Q: Why choose SIMUWU as a vacuum furnace manufacturer in China?

A: SIMUWU delivers advanced industrial vacuum furnace solutions with reliable quality and competitive cost for global customers.

For additional background information, you may refer to our related article on vacuum heat treatment principles.